1250 (41′) POWER PLAY

Boat Review on Powerplay 1250 Catamaran. Story and pictures by Bruce Hodgens

As power catamarans have increased in popularity in Australia and overseas, new designs are rapidly appearing. Powerplay Catamarans in Townsville are the latest Australian company to enter the market with the Powerplay 1250 catamaran. The first boat was recently launched and production on the second one is underway.

Powerplay Catamarans is a Townsville based boat building company owned by James and Nicole Dewing. James has been involved in building and designing boats for 20 years including working on America’s Cup boats, Pandora replicas for the North Queensland Museum and several monohulls and catamarans. He realized the potential for catamarans after building a 14 metre Simpson catamaran for a client in Townsville. The logical step was to go to a power catamaran to get good fuel economy and plenty of room. The first thing that strikes you about the boat is the beautiful lines. The hulls are very fair and blend into a curve at the rear to culminate in a boarding platform. The platform has radial stairs allowing easy access from a dingy or from the dock to the cockpit level. At the top of the stairs there is an engine room hatch that gives very easy access to the 75 horsepower Yanmar sail-drives.

The engine rooms also give access to the steering rams and rudderpost. A stainless steel gate can be closed at sea to reduce the risk of people wandering out the back The cockpit is very large and practical. The two rear berths take up some of the room but the seats around the edge make it easy to get up onto the side decks. There is seating across the back and front of the cockpit, with storage space under. An outdoor plastic table was located in the cockpit making it a great entertaining area outside. During the test run the table hardly moved. The cockpit has a roof that provides shade and protection from the elements.

Provision has been made for clears to be added if needed, but in the tropics where this boat will be working, plenty of shade is essential. The stairs to the flybridge are on the port side and do infringe into the cockpit a bit but it is hard to see where else you can have the ladder where it won’t be in the way Getting up onto the side decks is very easy, and the stanchion and safety lines are high to make even a rookie feel secure. I particularly liked the toe rail on the outside edge of the deck. On boats with a curved edge on their decks it is easy to slip and have to rely on the safety lines to stop you falling further. The deck is set down 50 mms forming the toe rail. The stanchion bases are all composite, as are the docking cleats. This greatly reduces the risk of leaks through the deck fittings, especially as they get older and loose. The side decks are quite wide and easy to negotiate even in rough seas.

One criticism I have of the side decks was the hatches fitted on them. I think it creates an unnecessary obstacle to unwary passengers, will be prone to damage and leaking and isn’t really necessary because it is only a passageway underneath and the side hatches provide plenty of light. However, according to James, the forward hatches were located on the walkway to ensure they were not over any of the berths. On the forward decks the toe rail continues. Stainless steel stanchions and rails continue all the way across the front of the boat and combined with the trampolines, give a large, safe area out the front. However, the feature that I really liked was a spar in the foredeck. This is quite deep and has a seat around the side at about half the depth. What a great place for a party. There are plenty of lockers across the front of the bridgedeck area for ropes and chain.

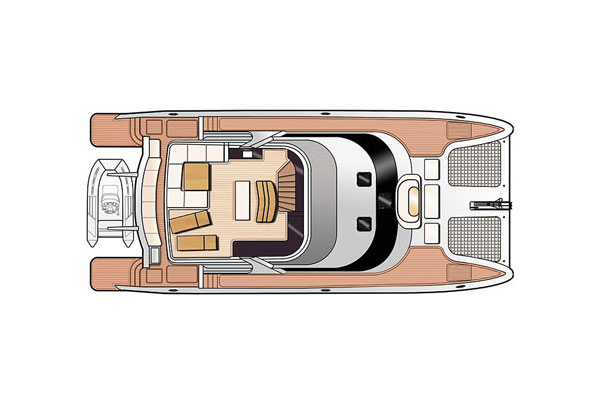

The anchor winch is set in a locker to keep the deck uncluttered and safe. On the hulls forward of the bridgedeck there are 2 enormous lockers. These allow access through a bulkhead to another forward locker. Both have floors at about 200mms above the waterline. Underneath these floors there is provision for water tanks, watermaker, genset etc. The lockers themselves have very good seals and would be ideal for storing all the toys that may be needed on a boat like this, including dive gear. The flybridge has full headroom, and even though this one is open, provision has been made to add clears if needed. Behind the wind breaker at the front is the instrument panel and controls.

A seating area has been incorporated into each side and is a favourite place to sit. Aerials, radar and solar panels are on the bimini hard top well out of the way. A variety of seating can be supplied depending on the client’s requirements. The stainless steel safety rails around the edge of the flybridge have seats incorporated into them. Being a catamaran, and thus very stable, no restrictions are necessary on the number of people on the flybridge. In the tropics this is the best place to be on a hot day when underway. There is no hatch at the top of the stairs, allowing rain to go down into the cockpit, but I’m sure this could be added if needed.

On this boat, there is only one steering station and that is on the flybridge. It is an option to have a lower steering station, but this is a workboat, and so that wasn’t deemed necessary. I was eager to get under way and see how she performed, but decided that it would be better to get the inside inspection out of the way first.

Going back down the stairs from the flybridge was relatively easy. The steps are on a stainless steel tubes with timber treads. Once back in the cockpit you enter the saloon through a large, slightly off centre door. There are large windows on either side of the door. The first impression is a huge, open and airy saloon.

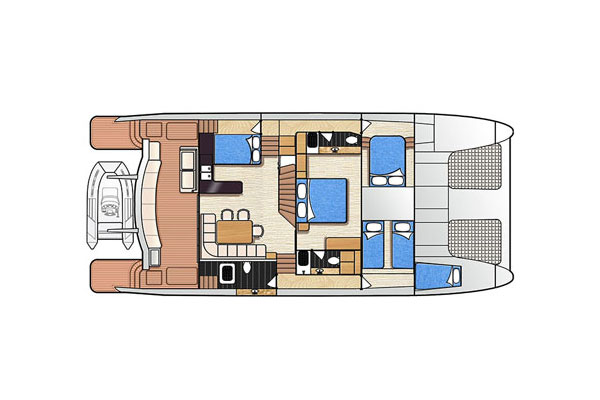

This boat was built for the backpacker market and has what James refers to as a “hose down” finish. It is a very practical finish in a vinyl fleck paint that is basically white with blue flecks through the paint. This is then oversprayed with a clear flat finish to make it very easy to clean. All the higher wear areas such as the galley and seat fronts are painted in 2 pack polyurethane. On the starboard side of the saloon at the rear is a large galley. This boat will sleep at least 14 so it requires a good-sized galley. The bench tops are a moulded fibreglass construction with a mid blue finish. The basins, edges and splash back are all moulded in. The overall effect is very neat. There is a stove and oven built in and a fridge under the bench with a front opening door.

On the port side there are similar bench tops incorporating a large top loading freezer (200 litres) and a navigation table with all the electrical switchgear, GPS chart plotter (which double as a flat screen TV) and a DVD player. In the forward part of the saloon is a semi circular settee with a large table. There is an abundance of storage under all the seats and in the cupboards in the galley and the nav area. The large wrap around windows accentuates the open, airy feeling. These give excellent visibility but in the tropics you need to have a darker tint or shade covers over them to reduce the heat entering the saloon.

Easy access via 3 steps finds you standing in the large volume hulls. The use of portholes and hatches makes it feel open and airy, with no feeling of claustrophobia. The aft cabins are fitted with queen sized double berths and there is plenty of storage space and even a hanging locker. The forward cabin is also fitted with a queen size berth, and in this boat, an extra double berth is fitted over the bridgedeck. Remember this boat will be used for backpacker trips and it is critical to maximise the number of beds. Once again there is plenty of storage space and hanging lockers.

Centrally located between the forward and rear berths is a head and shower. There is adequate room to walk past the head to get to the forward berths. The head is finished in 2-pack polyurethane paint for easy maintenance, and has the same moulded bench tops incorporating the basin. The head is fairly small by most people’s standards, but is satisfactory for a boat. The other hull layout is a mirror image of this hull. Time to fire up the ponies and see what this cat will do. The 75 horsepower Yanmars are the 4 cylinder turbo charged models. The engine rooms are well insulated and you had to listen carefully to see if they were running. We cast off the lines and motored out.

The first thing I noticed was the indirect steering. It is 5 turns lock to lock using hydraulics and with small rudders there seems to be a lot of wheel turning until you get used to it. The steering was light during all manoeuvres, so perhaps a re-think on the gearing would improve this. We headed out of Townsville harbour dodging the ferries, a barge to Magnetic Island and other small recreational craft. The visibility from the flybridge is fantastic, and would be particularly good out at the reef. Once we cleared the harbour we entered open water.

On the test day it was blowing 15 knots from the southeast. It created the usual Cleveland Bay chop, that is, very short, steep waves. We increased revs to cruise speed and headed straight into the chop. This created quite a bit of spray over the front hulls and through the trampolines. Perhaps a closer-knit fabric for the trampolines would minimise the spray over the boats. These trampolines were made of 6 mm polyester braid 40 mms apart and running both north-south and east-west. Other than the occasional spray from larger waves, the catamaran handled the chop with ease at all speeds.

At higher speeds the ride smoothed out as the hulls cut through the waves rather than going up and down the wave faces. There was no slapping of waves under the bridgedeck thanks to the high bridgedeck clearance. Going side on to the waves was relatively smooth compared to monohull boats I have been on. Instead of that slow roll you had a fairly small but sharp change as the waves went under the hulls. Going down wind was very directionally stable.

There was no sign of broaching and in fact, there was little need to steer at all. We were soon surfing the waves at 16 and 17 knots. Full lock turns were done at full speed in about 5 boat lengths with no vibration or fuss. Next I checked performance on one motor. The boat maintained a straight course after the initial correction with the rudder, and would present few problems if a motor failed. To do all the speed test work I brought along a hand held Magellan GPS rather than trust the speed log. All the speed tests were done in flat water with no current and with the wind side on.

The fuel consumption comes from the Yanmar fuel curves and is for one engine. At 2000 RPM and 5.6 litres per hour we averaged 6.8 knots; 2500 RPM and 7.4 litres per hour, 7.7 knots; 3000 RPM and 9.33 litres per hour, 10.1 knots; 3600 RPM (maximum continuous revs) and 9.9 litres per hour, 13.7 knots; and flat out at 3900 RPM and 10.53 litres per hour,15.5 knots. The turbo charged motors are very smooth and quiet, and even at 3900 RPM don’t sound at all busy. The boat had half full fuel tanks (maximum capacity 385 litres) and full water tanks (1400 litres) with 2 people on board for the test. Even fully loaded this boat should comfortably cruise at 10 knots and use less than 20 litres per hour in fuel.

This is fantastic. Most of the flybridge cruisers I have been on would have double this fuel consumption at these speeds. Time to head back to the marina. After cruising smoothly along at 13 knots, it was difficult to pull the throttles back for the 6 knot speed limit in the harbour. Manoeuvring the boat to come alongside the dock was a breeze with twin motors. They are counter rotating props so there is no prop walk to worry about. I centred the helms and just used the throttles to spin the boat around in its own length and bring it into its pen at the marina. Couldn’t be easier. There is a fair bit of windage on the boat, but even in 15 knots of wind there was little fuss docking. Overall this boat is a credit to James and his team at Powerplay catamarans..

It looks great, is economical to run and the spacious interior is excellent for private or charter operations. Powerplay Catamarans have picked a real winner. It is also particularly pleasing to see a company “putting its money where its mouth is”. Most boat builders will happily build a new design boat for a customer, but James has financed the first boat himself to prove the concept. It has certainly paid off because the next boat, a 50 footer, is already underway, and negotiations are almost finalised for a third client. Powerplay Catamarans are now building a range of boats including an 11.5 metre, 12.5 metres, 14.5 metre and a 16 metre based on developments of this boat. The hulls, bulkheads and decks are all balsa cored epoxy glass, and will be built to survey. Polyester mouldings have been made for all the internal furniture.